When choosing between attribute and variable testing, consider your inspection needs. Attribute testing offers quick, simple checks to classify items as good or defective, making it ideal for fast decisions and easy implementation. Variable testing provides detailed measurement data, helping you monitor subtle process shifts and make precise improvements. Understanding these differences allows you to select the best method for your quality goals—stay with us to explore how to pick the right QC tool for your needs.

Key Takeaways

- Choose attribute testing for quick, cost-effective assessments when defects are easily identifiable and binary decisions suffice.

- Opt for variable testing when detailed measurement data is needed for process control and detecting subtle quality shifts.

- Attribute testing simplifies data collection and analysis but offers less insight into process variations.

- Variable testing provides richer, more precise data, enabling comprehensive analysis and continuous improvement.

- Consider product complexity, quality goals, and resource availability to select the most suitable QC tool.

When it comes to testing in quality control and decision-making, understanding the difference between attribute testing and variable testing is essential. Both methods help you assess product quality, but they do so in different ways, guiding your data collection and statistical analysis processes accordingly. Knowing which approach fits your specific needs can considerably impact the accuracy of your results and the efficiency of your operations. Attribute testing focuses on categorizing items based on whether they meet or fail a certain standard. Think of it as a binary decision: is the product acceptable or defective? This method is straightforward and involves counting the number of defective units in a sample. For example, inspecting a batch of bottles for cracks or contamination involves simple yes/no checks. Because of its simplicity, attribute testing requires less detailed data collection, but it can also limit the depth of your statistical analysis. You primarily analyze defect counts or proportions, which makes it easier to interpret but less sensitive to subtle variations in quality. This approach works well when you need quick assessments or when defects are easily identifiable. Variable testing, on the other hand, measures specific quality attributes on a continuous scale. Instead of just noting if a product is good or bad, you measure how much it deviates from a standard. For instance, you might record the exact weight, length, or tensile strength of a product. This method involves more detailed data collection, capturing precise measurements that can be analyzed statistically to identify patterns and trends. The data collected facilitates sophisticated statistical analysis, such as calculating means, variances, and control limits, giving you a clearer picture of process performance. Variable testing is more sensitive to small shifts in quality, making it ideal for process control and continuous improvement. Incorporating Glycolic Acid benefits into skincare routines exemplifies the importance of precise measurement and analysis to achieve optimal results. Choosing between attribute and variable testing depends on your specific goals and the nature of your products. Attribute testing is quick, simple, and cost-effective, suitable when defects are obvious and quick decisions are needed. Variable testing, however, requires more time and effort but provides richer data, enabling you to detect subtle process variations and make more informed decisions. Both methods are valuable tools in your quality control arsenal, and understanding their differences helps you tailor your data collection and statistical analysis to achieve the most accurate and meaningful results. Ultimately, selecting the right testing method ensures you maintain high product quality, optimize your processes, and make smarter, data-driven decisions.

attribute testing QC tools

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Frequently Asked Questions

How Do I Determine Which Testing Method Suits My Product Type?

When choosing a testing method, consider your product’s complexity and the measurement precision you need. For simple products with clear pass/fail criteria, attribute testing works well. But if your product requires detailed measurements and high accuracy, variable testing is better. Think about how precise your measurements must be and how complex your product is to select the most suitable QC tool, ensuring reliable quality control.

Can Attribute and Variable Testing Be Combined Effectively?

Yes, you can effectively combine attribute and variable testing through hybrid approaches. This method leverages data integration, allowing you to gather complete quality insights. By doing so, you optimize your QC process, balancing detailed data with quick assessments. Hybrid approaches help you adapt to different product aspects, making your quality control more flexible and robust, ensuring you catch defects efficiently while maintaining high standards.

What Are the Cost Differences Between Attribute and Variable Testing?

When considering cost implications, attribute testing is generally cheaper upfront but less precise, leading to potential rework costs. Variable testing, while more expensive initially due to advanced equipment, offers greater measurement precision, reducing errors and rework over time. You should weigh these factors based on your quality goals and budget; choosing the right tool balances upfront costs with long-term efficiency and accuracy.

How Does Sample Size Impact the Accuracy of Each Testing Method?

Sample size directly impacts sampling precision and data variability in testing methods. With larger samples, you’ll improve accuracy for both attribute and variable testing, reducing data variability and increasing confidence in results. Smaller samples may lead to less precise outcomes, especially in attribute testing where you might miss subtle defects. To guarantee reliable results, adjust your sample size based on the desired accuracy and the variability inherent in your data.

Are There Industry Standards Guiding the Choice Between Attribute and Variable Testing?

You should know that industry standards and testing guidelines help you decide whether to use attribute or variable testing. These standards, often set by organizations like ISO or ANSI, provide clear recommendations based on your product type, inspection goals, and accuracy needs. By following these guidelines, you guarantee your quality control process aligns with best practices, optimizing your testing approach and maintaining compliance.

165ft/50m Laser Measure Ft/in/M Switching LM50 Laser Measurement Tool Devices with 2 Bubble Levels Distance Meter,Large Backlit LCD

▲HIGH ACCURACY&STABILITY – Using laser precision technology, accuracy up to ±1/16 inch, measurement distance extends up to 196ft/50m;…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Conclusion

Choosing between attribute and variable testing is like selecting the right tool for a job—each has its own purpose and strengths. By understanding their differences, you guarantee your quality control process is as precise as a surgeon’s scalpel. Don’t settle for a one-size-fits-all approach; pick the tool that best fits your needs. With the right choice, you’ll build a quality system that’s as solid and reliable as a well-crafted bridge.

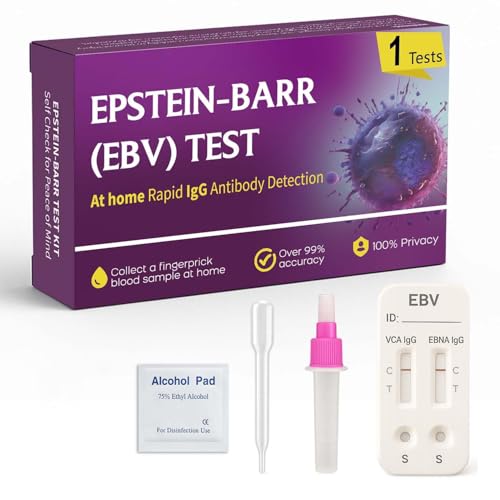

EBV at-Home Test Kit | Detects IgG Response to VCA & EBNA | 15-Minute Rapid Result | Easy Fingerstick Sample

Quick At-Home Screening – Designed for personal use, this test provides insight into your body’s immune response to…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.

Digital Caliper, Adoric 0-6" Calipers Measuring Tool – Electronic Micrometer Caliper with Large LCD Screen, Auto-Off Feature, Inch and Millimeter Conversion

Precise measurement: Measurement range: 0 – 6''/0 – 150 mm; Resolution: 0.01”/0.1 mm; Accuracy: +/- 0.2 mm/0.01”. Perfect…

As an affiliate, we earn on qualifying purchases.

As an affiliate, we earn on qualifying purchases.